Ensuring Safety with Superior Hand Protection

A GUIDE TO HAND PROTECTION

AUSTRALIAN STANDARDS FOR HAND PROTECTION

The Australian / NZ Standard is AS/NZS 2161.

Historically, when developing and updating many Australian & New Zealand Standards (AS/NZS) for hand protection, Standards Australia have turned to their European (CE) counterparts and have adopted their standards for Australia. Additionally, standards developed by the International Organization for Standardization (ISO), of which Standards Australia is a member, have also been adopted.

CUT RESISTANCE LEVELS

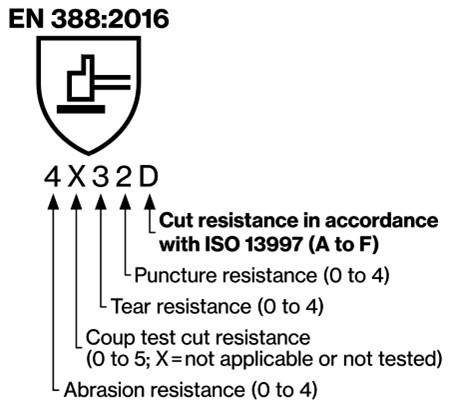

The cut levels for gloves under the old EN 388:2003 standard used a different scale than the updated EN 388:2016 standard. The old EN 388:2003 standard classified cut resistance into levels ranging from 1 to 5, with each level representing a specific range of cut resistance.

The EN 388:2016 standard replaced this system with a more precise testing method using the ISO 13997 test. In this updated system, cut resistance is rated on a different scale (A through F) which provides a more accurate measurement of cut resistance when it comes to hand protection. The standard evaluates gloves based on their performance against abrasion, cut, tear, puncture, and impact, ensuring that users can select the appropriate hand protection for various industrial and occupational hazards. Following EN388 guidelines ensures that both manufacturers and users can have confidence in the reliability and safety of their hands whilst carrying out work.

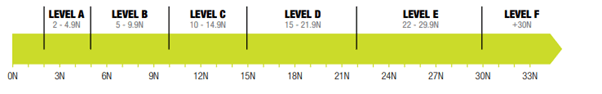

NEW STANDARD CUT RATINGS

Gloves can withstand a cutting force of 2 – 4.9 newtons (204 – 508 grams)

This is the lowest cut resistance level and indicates that the gloves offer basic protection against cuts and abrasions

Gloves can withstand a cutting force of 5 – 9.9 newtons (509 – 1019 grams)

This level of protection is suitable for tasks that involve a moderate risk of cuts and abrasions, offering more durability and safety than Level A gloves.

Gloves can withstand a cutting force of 10 – 14.9 newtons (1020 – 1529 grams)

These gloves are suitable for tasks with a higher risk of cuts and abrasions. They are commonly used in industries such as manufacturing, construction, and logistics, where handling sharp materials or tools is common.

Gloves can withstand a cutting force of 15 – 21.9 newtons (1530 – 2242 grams)

This level of cut resistance is suitable for tasks involving a significant risk of cuts and abrasions, such as handling sharp-edged materials, tools, or machinery

Gloves can withstand a cutting force of 22 – 29.9 newtons (2243 – 3058 grams)

This level of protection is often used in industries where workers are exposed to sharp objects or high-risk environments, such as heavy manufacturing, construction, or metal handling.

Gloves can withstand a cutting force of 30+ newtons (3059+ grams)

These gloves are designed for tasks with the highest risk of cuts and lacerations, such as handling very sharp tools or materials. They are typically used in industries where extreme cut protection is required, such as in heavy manufacturing, metal processing, or other high-risk environments.

Two Effective Testing Methods of Work Gloves for Optimal Cut Protection

The most distinct component to the EN 388 2016 standard is the formal inclusion of the ISO 13997 cut test method. ISO 13997, also known as the “TDM-100 Test”, is similar to the ASTM F2992-15 test method used in the ANSI 105 standard. Both standards make use of the TDM machine with the sliding blade and weights. After many years of using differing testing methods for hand protection, it was discovered that the blade in the “Coup Test” would dull quickly when testing yarns with high levels of glass and steel fibers. This led to unreliable cut scores, highlighting the need for the inclusion of the “TDM-100 Test” to incorporate the EN 388 standard to ensure more accurate hand protection assessments.

OLD STANDARD CUT RATINGS

Gloves can withstand a cutting force of approximately 1.2 to 2.0 newtons.

Gloves can withstand a cutting force of approximately 2.1 to 3.0 newtons.

Gloves can withstand a cutting force of approximately 3.1 to 5.0 newtons.

Gloves can withstand a cutting force of approximately 5.1 to 10.0 newtons.

Gloves can withstand a cutting force of more than 10.0 newtons.

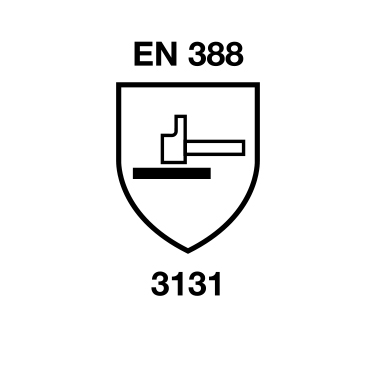

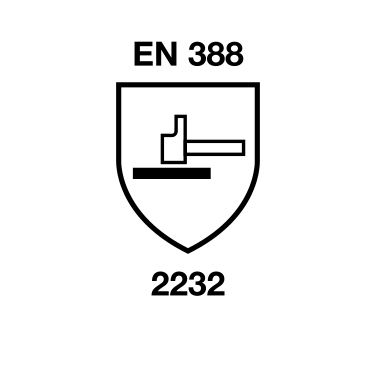

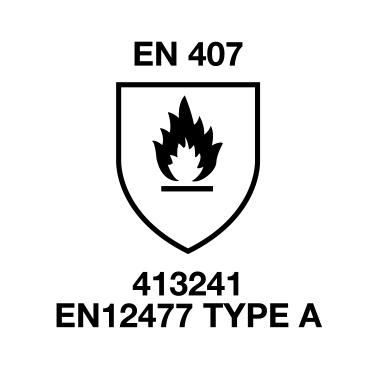

HOW DO I KNOW WHAT RATINGS GLOVES ARE ?