ENGINEERING

ENGINEERING

Engineering fabrication, assembly and refurbishment processes need different handling techniques. Maintaining productivity and safety in an engineering workshop calls for flexible solutions. Absolute Lifting and Safety can help with:

- customisable lifting and shifting solutions

- inspections and testing of equipment

- specialised lifting advice for engineered lifting products

- industry-specific PPE customised to the engineering environment

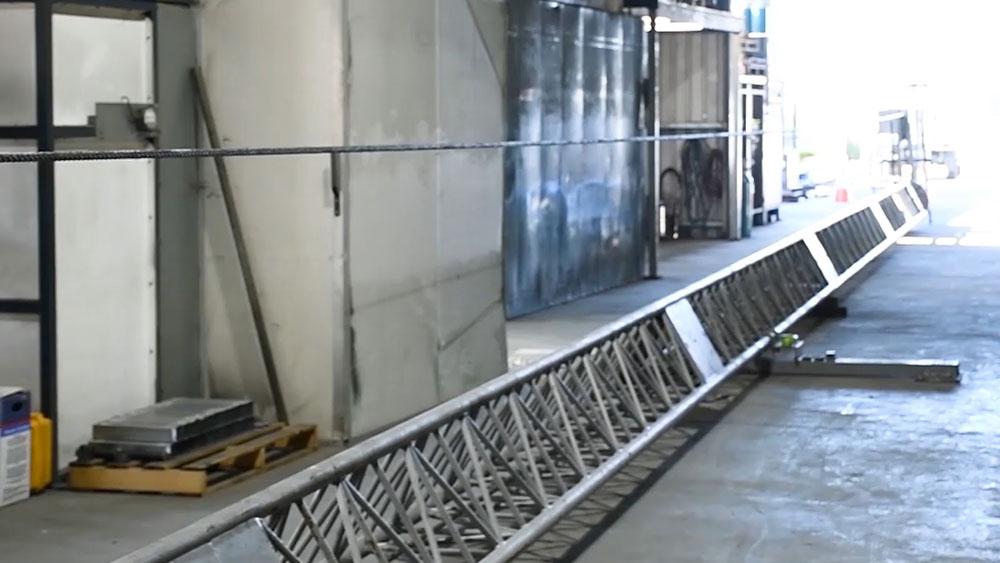

Engineering Customisable Lifting and Shifting Solutions

In an ever-changing environment in which the machinery parts you’re working on vary in size and weight, it’s easy to overlook handling and safety details. Absolute Lifting and Safety will work closely with you to gain a clear understanding of your specific equipment requirements. These include:

- hoists and winches: based on your workshop facilities, we can supply manual, electric or pneumatic hoists.

- overhead gantry, monorails and portal gibs

- slings: We can advise on nylon vs chain slings

- lifting beams and devices

- bolt-on and weld-on lifting eyes

If you have questions about what equipment is best for the job, we can talk you through the properties of each of our products, and together we can work out options best suited to your desired outcomes.

Testing Equipment

Our range of machines for specialist testing includes a leading-edge mobile test bed truck that we can bring to your workshop simply for your convenience, or to avoid production delays. Whether it’s for the lifting and safety equipment in your workshop, or for products you’re manufacturing, we can work alongside you to test:

- tensile strength

- sheer strength

- working load limit

- force measuring and weighing applications

- counterweight load testing

ENGINEERING Inspections and Certifications Management

Equipment that is damaged or overdue for inspection is what every workshop needs to avoid. Absolute Lifting and Safety offers an asset management service to ensure that all lifting and safety equipment in your workshop is certified and remains fit for use. Using our cloud-based CORE software, we ensure:

- programmed inspections are performed

- all testing and tagging is kept up to date

- logging of all new equipment prior to despatch

- worn, defective or expired equipment is removed from service

We’ll provide you with traceability, accountability and reporting to ensure required compliance and due diligence.

Success Stories:

Customised lifting solution for Sulzer’s heavy-duty armatures

Sulzer needed a safe method of lifting costly, fragile 8.5-ton armatures to complete a refurbishment process. Together with RUD engineers, Absolute Lifting and Safety designed, engineered and fabricated an armature lifting device. Our solution included an easy connection point using a C-shaped adjustable top with coupling below, which resulted in zero contact during the lift. The outcome was so effective that the device was incorporated into Sulzer’s general practice procedures. Since it requires no specific expertise to operate the lifting device, a wide scope of workers can perform the lifting task.

Structural testing of a telecommunications tower before commissioning

Absolute Lifting and Safety strength-tested a telecommunications tower section using a wire rope assembly and load cell at Wiltec Industries’ workshop. Our testing provided essential structural feedback on the prototype’s capacity in each stage of development.