Respirable Crystalline Silica

Managing the risks of respirable crystalline silica from engineered stone in the workplace

Working with engineered stone can expose workers, and other persons, to the risks of respirable crystalline silica (silica dust). Exposure to silica dust can have serious health effects, including fatal lung disease.

The below article covers some areas outlined in the new Code of Practice (October 2021) for managing the risks of respirable crystalline silica from engineered stone in the workplace.

For a comprehesive list of controls and managing the risks for respirable crystaline silica see SafeWork Australias Code of Practice

What is respirable crystalline silica?

Respirable Crystalline silica is the crystalline form of silicon dioxide, a naturally occurring mineral that forms a major component of most rocks. It is found in natural stones like granite and sandstone and is used to create artificial products like engineered stone and tiles.

When dust is created through natural or artificial means it comes in a range of sizes, from very small (less than 10 micrometres [µm] in diameter) to larger particles that can be seen with the naked eye. Dust that is less than 10 µm in diameter is known as respirable dust as, when inhaled, it travels deep into the lungs.

Health effects of Respirable Crystalline Silica dust

Respirable Crystalline Silica dust is a significant health hazard for workers. Very small particles of silica dust cannot be seen under normal lighting or with the naked eye and stay airborne for long periods of time. When airborne, workers can easily inhale the small silica dust particles deep into their lungs where it can lead to a range of respiratory diseases, including:

- silicosis

- progressive massive fibrosis

- chronic obstructive pulmonary disease

- chronic bronchitis, and

- lung cancer.

Silica dust also increases the risk of developing chronic kidney disease, autoimmune disorders (such as scleroderma and systemic lupus erythematosus) and other adverse health effects, including an increased risk of activating latent tuberculosis, eye irritation and eye damage.

About Silicosis

| Silicosis type | Exposure type | Respiratory impact of exposure |

| Acute | Can develop after short-term and very high levels of silica dust (for example less than one year, and after a few weeks). | Causes severe inflammation and protein in the lung. |

| Accelerated | Results from short term exposure to large amounts of silica dust (1 to 10 years of exposure). | Causes inflammation, and protein and scarring in the lung (fibrotic nodules). |

| Chronic | Results from long term exposure (over 10 years of exposure) to low levels of silica dust. | Causes scarring of the lung and shortness of breath. |

Damage to the lungs from silica dust and symptoms of disease (such as lung cancer, silicosis and progressive massive fibrosis) may not appear for many years. Workers may not show any symptoms, even at the point of initial diagnosis, which is why prevention and health monitoring are critical. Health monitoring requirements for workers who work with engineered stone are detailed in Part 3.3 of this Code.

There is no cure for silicosis. However, all silica dust-related diseases are preventable through using effective controls throughout the lifecycle of the product to eliminate or minimise exposure to silica dust at the workplace

How to manage and control the risks from working with engineered stone & Respirable Crystalline Silica

WHS Act section 17

Management of risks

Risks arising from working with engineered stone must be eliminated or minimised so far as is reasonably practicable to protect workers and other persons against harm.

Risk management is a proactive, systematic process that helps a PCBU plan and respond to potential hazards and their associated risks in the workplace. It involves four steps:

- identifying the hazard

- assessing the risk

- controlling the risk, and

- reviewing control measures.

Identifying the hazard with Respirable Crystalline Silica

A hazard is a situation or thing that has the potential to harm a person.

For engineered stone, the hazard is the respirable crystalline silica dust generated through certain mechanical processes.

To identify the likely sources of silica dust, it is important for a PCBU to consider the following aspects of the workplace and their interactions:

- the design and manufacture of the engineered stone, including the percentage of crystalline silica

- physical work environment

- for example, the layout of a workshop

- equipment, materials and substances used

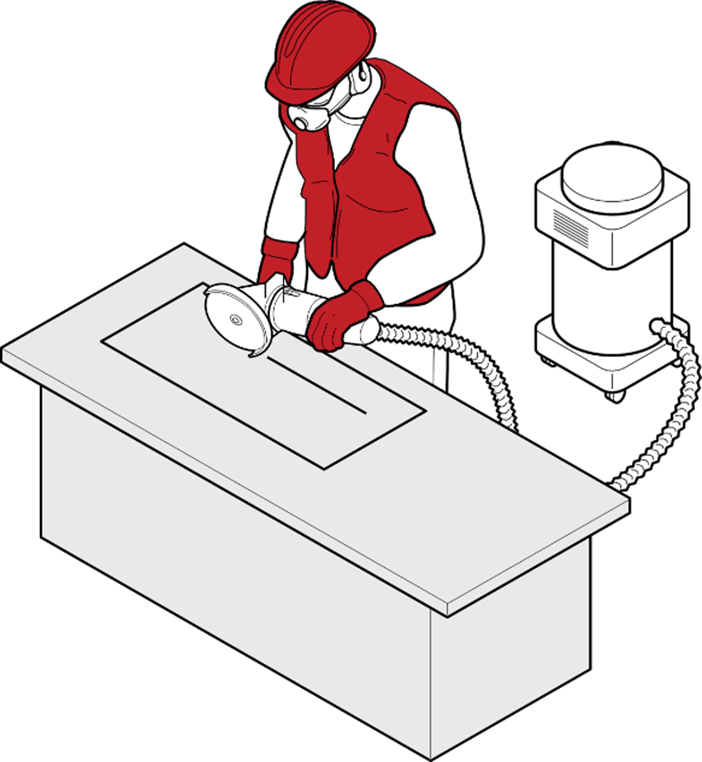

- for example, using angle grinders

- work tasks and how they are performed

- for example, grinding engineered stone which generates silica dust

- work design and management

- for example, a lack of consideration of the product supply chain and lifecycle when designing good work practices and product risk management, and

- worker experience, knowledge and behaviours.

This may be achieved by:

- conducting a walk-through assessment of the workplace

- observing the work and talking to workers and/or HSRs about how work is carried out

- inspecting the plant and equipment that is used as part of the fabrication and other relevant processes

- for example, hand-held tools may generate more silica dust than automated machinery

- undertaking air monitoring at the workplace

- inspecting workplace surfaces for build-up of settled dust, and

- reading product labels, safety data sheets and manufacturers’ instruction manuals.

Assessing the risks of Respirable Crystalline Silica

A risk assessment for Respirable Crystalline Silica involves considering what could happen if a worker is exposed to a hazard and the likelihood of it happening.

Hazards have the potential to cause different types and severities of harm, ranging from minor discomfort to a serious injury, illness, disease or death. Exposure to silica dust can adversely affect a worker’s health, including developing silicosis, progressive massive fibrosis, chronic obstructive pulmonary disease, chronic bronchitis and lung cancer.

Assessing the risks of Respirable Crystalline Silica will help to:

- identify which workers are at risk of exposure to Respirable Crystalline Silica dust

- determine what sources and processes are causing that risk

- identify what kind of control measures should be implemented to control the risk

- check the effectiveness of existing control measures to control the risk

- determine the severity of the risk, and

- determine how urgently action may need to be taken.

The nature and severity of risks will depend on various factors, including the:

- percentage of respirable crystalline silica in the engineered stone

- for example, some engineered stone can have over 90 per cent crystalline silica, while others may have a lower percentage

- task being undertaken

- for example, angle grinding can generate more silica dust than other tasks

- equipment being used

- for example, hand-held tools may generate more silica dust closer to the worker’s breathing zone than automated machinery

- conditions under which the work with engineered stone is carried out

- for example, work undertaken in an isolation booth or in an open plan workshop, and

- skills, competence and experience of the worker.

The potential of exposure of administrative workers to silica dust at fabrication workplaces should also be considered. These workers may be exposed if:

- adequate controls are not implemented, and subsequent background levels of silica dust are high, or

- their roles mean they frequently access processing areas

- for example, administrative workers that frequently walk through or perform tasks in areas near where the processing of engineered stone is undertaken may be exposed to high levels of silica dust.

A PCBU should review the information on the product labels, and any available safety data sheets, to assist in determining the type and severity of the harm. The following questions may help a PCBU to assess the risk:

- How much silica is in the products at the workplace?

- How often, and for how long, might a worker be exposed to silica dust?

- What are the scenarios that may cause workers to be exposed to silica dust?

- for example, are they exposed to silica dust when it is freshly generated or during housekeeping tasks after dust has accumulated?

- Is there evidence of exposure to silica dust?

- for example, are dust clouds evident near workers when engineered stone is cut?

- What are the conditions under which the work is carried out?

- for example, is work on engineered stone carried out in an enclosed space that is isolated from workers?

- What are the skills, level of competence and experience of workers?

Respirable Crystalline Silica dust control plan

A silica dust control plan is a practical tool for a PCBU that is informed by a risk assessment. It can help a PCBU identify all potential tasks that may result in exposure, or possible exposure, to silica dust and the control measures to eliminate or minimise that exposure.

A silica dust control plan should consider ways to:

- eliminate or minimise the amount of silica dust being generated and released into the air

- prevent silica dust being breathed in by workers

- clean up any silica dust, slurry or other waste produced, and

- decontaminate workers’ clothing, footwear and protective equipment.

A silica dust control plan should include details on:

- the percentage of crystalline silica in the product being used, as the higher the percentage the higher the level of silica in the dust and the greater the risk

- all sources of silica dust in the workplace

- the dust control measures implemented for each activity

- how dust control measures are integrated into daily shift routines, for example, tool box talks, pre-start checks and daily cleaning of work areas

- how air monitoring is used to assess whether the controls are working

- the systems in place to routinely inspect, maintain and monitor controls and equipment to ensure they are clean and functioning effectively

- ongoing monitoring and review strategies, particularly in response to incidents, control failure or where the workplace exposure standard is exceeded, and

- how risks, controls and any control failures, and where the workplace exposure standard is exceeded, are communicated and reported.

Where a PCBU has decided to develop a silica dust control plan, it must be developed in consultation with workers involved in carrying out the tasks and the HSR, where there is one.

A PCBU may also share the silica dust control plan with the registered medical practitioner carrying out or supervising health monitoring. This will allow the registered medical practitioner to identify any possible source of silica dust exposure, taking into account the control measures in place.https://widadmusic.com/etichetta-sessuale-come-comportarsi-a-letto/