Table of Contents

Forklift Jib Safety Concerns: Addressing Irreversible Deformation and Lifting Capacity

In this article you will learn about Forklift Jib Safety. More importantly we will cover the risks of irreversible deformation and decreased lifting capacity in forklift jibs, and why it’s crucial to remove them from service to ensure safety.

When it comes to forklift jibs safety is paramount. However, there are instances where irreversible deformation can occur in the Jib extension and safety hook due to stress. In such cases, it is crucial to address these concerns promptly to prevent any potential hazards.

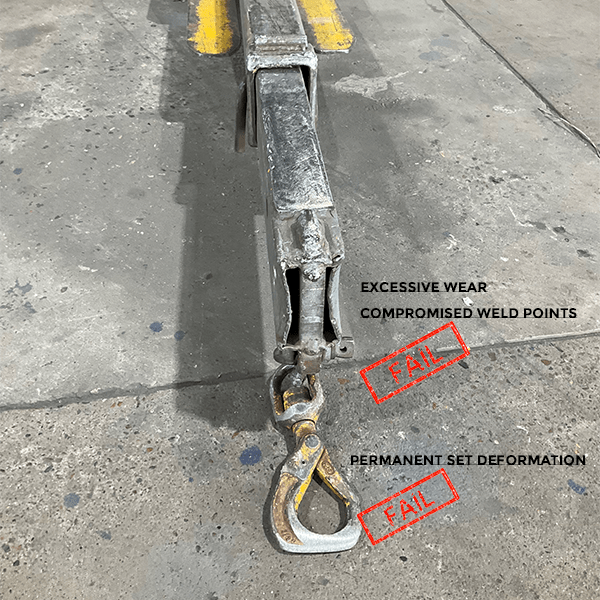

One major red flag is when the Jib extension and safety hook show signs of irreversible deformation after being subjected to stress. Irreversible deformation refers to permanent damage or warping that alters the structural integrity of the Jib, making it unsafe for use. Common causes of irreversible deformation can include overloading, rough handling, or wear and tear over time.

If irreversible deformation is detected in a forklift jib, it is essential to take immediate action. Continuing to use a compromised Jib can pose serious risks to operators, loads, and the overall workplace safety. For instance, the lifting capacity of the Jib may be significantly degraded, leading to potential accidents or damage to the load and equipment.

To ensure safety of personnel and operations, the Jib should be removed from service immediately when irreversible deformation is detected. It is crucial to follow established safety guidelines and procedures, and consult with qualified professionals for proper inspection, repair, or replacement of the Jib.

Addressing irreversible deformation and lifting capacity concerns in forklift jibs is crucial for workplace safety. Detecting and addressing these issues promptly can prevent accidents, protect personnel and equipment. Remember to always prioritize forklift jib safety and follow best practices when it comes to forklift jib maintenance and usage.

This forklift Jib should be removed from service.

Common sense is a fundamental aspect of workplace safety, yet it can often be overlooked.

Ensuring safety in the workplace should never be compromised, and common sense should always prevail. Have you adopted safe work practices such as conducting pre-inspections before using a forklift jib?. In this section, we emphasize the importance of having inspections carried out by competent individuals in accordance with Australian Standards.

Common sense is a fundamental aspect of workplace safety, yet it can often be overlooked. Taking practical steps, such as conducting pre-inspections, can greatly contribute to maintaining a safe work environment. Pre-inspections involve carefully assessing the condition of the forklift jib before each use. Checking for any signs of wear and tear, damage, or deformations that may compromise its safety and performance is critical.

It is also crucial to ensure that regular inspections are carried out by competent persons who are knowledgeable and experienced in forklift jib safety and compliance with Australian Standards. This can help identify any potential issues early on and prevent accidents or incidents that may result in serious consequences.

In conclusion, prioritizing safety in the workplace requires common sense and adherence to safe work practices, such as pre-inspections carried out by competent individuals. Timely identification and rectification of any safety concerns are crucial to prevent accidents and ensure a safe work environment. Remember to always prioritize safety and compliance when it comes to forklift jibs and other equipment.

Australian Standards AS 2359.1:2015 – S E C T I O N 6 F O R K A R M S A N D A T T A C H M E N T S

6.1 FORK ARMS

Fork arms shall comply with requirements of AS 2359.14—2005, Clause 6.1.

6.2 FORK LIFT ATTACHMENTS

6.2.1 Specified capacity

The capacity of truck attachments shall be at least equal to the actual capacity of the truck, fitted with that attachment, or the actual capacity of the truck shall be derated.

6.2.2 Design requirements

The attachment shall comply with at least one of the following:

(a) The attachment shall be designed to withstand, at the designated load centre distance, a static central load of 2.5 times its specified capacity.

(b) The attachment shall be designed in accordance with AS 3990 or equivalent technical standard where applicable. The design shall take into account all dynamic loads and forces and, based on the intended life of the equipment, shall include a fatigue stress analysis of known critical stress-raising areas such as cutouts and base material next to welds.

(c) The attachment shall be designed to withstand dynamic endurance testing under effective loads appropriate to the specified application of the attachment over its intended design life. (This preferred option is practicable for large quantity

manufacture only, due to the prohibitive costs involved.)